As we move further into the world where the embodied carbon of a building is outweighing operational carbon in its predicted lifetime, the impact of a building’s structure becomes more and more prevalent in the discussion and decision-making process of the early stage design. Design Director Steve Toon outlines how CLT/concrete hybrid structures can sometimes be more efficient than using alternate materials.

The embodied carbon vs operational carbon of a building debate often leads us to the dilemma of whether we jump on the mass timber agenda, or do we stick to more carbon lean versions of the more tried and tested materials? This is a quandary for all engineers, architects and ultimately clients to resolve. The decision is by no means clear-cut.

If we compare some of the key benefits and drawbacks of both concrete and timber when applied to a speculative commercial office build, we can generally conclude the following:

| Timber | Concrete | |

| Good | Low carbon (or even carbon negative) possibilities | Inherently robust and durable |

| Exposed timber enhances wellbeing and aesthetic | Inflammable | |

| Continuous source of raw material if farmed sustainably | Flat flush soffits readily achieved | |

| A light material, reducing foundation costs and resulting carbon footprints | Slim floor build-up solutions | |

| High GGBS can significantly reduce the carbon footprint | ||

| Not so good | Cannot achieve comparable spans in the same depth | Not a sustainable source of raw material and the carbon footprint cannot be zero |

| Inherently flammable. Measures needed to limit combustion, and the larger proportion of a structure that’s timber the greater the risk profile. | Heavy, so has impact on other parts of the structure’s footprint | |

| Lacking in ultimate durability and weathering resistance. | ||

| To truly ‘capture’ the embodied carbon the timber can never be incinerated or landfilled. Ever. |

As with all the challenges we find in life, those in the built environment very rarely have that ‘silver bullet’, a holistic solution that answers both environmental and building requirements. Constructing workplaces solely in mass timber is not necessarily the answer to our problems. In addition to the climate emergency, we must consider the requirements of the building and its users in parallel.

Developers now have to devise ways of significantly reducing the carbon footprint of their future developments. Many developers in the UK have set their project teams the goal of achieving the RIBA 2030 target for total embodied carbon. This is an ambitious target, and some would argue an all mass timber solution is actually the ‘silver bullet’ to all of a designer’s problems. But when so many opposing requirements and metrics sway the decision away from mass timber solutions, not all developers are jumping onto an all timber resolution

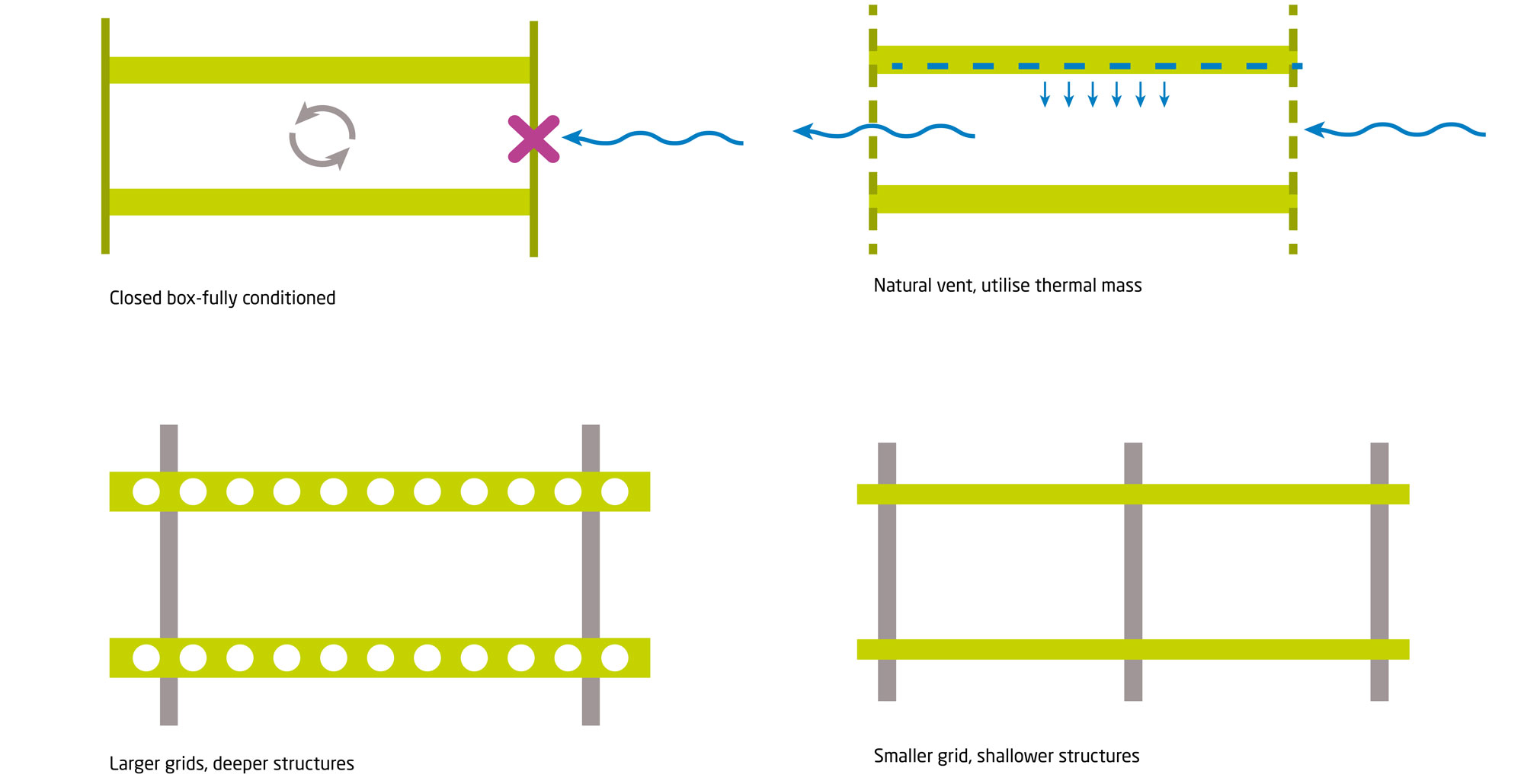

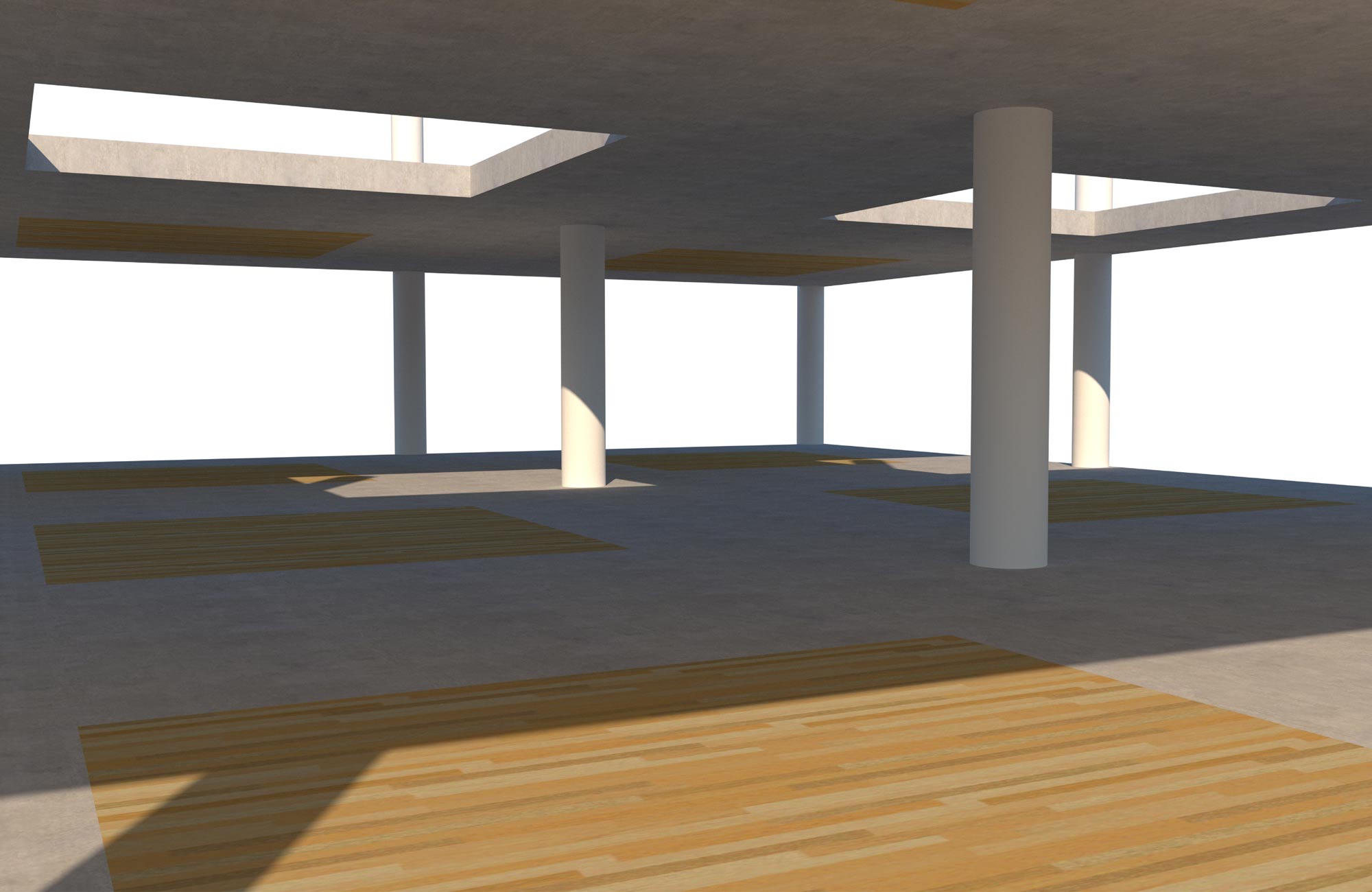

On many of our commercial projects, AKT II is working up a bespoke hybrid concrete/timber solution that meets many of the opposing needs of the modern workplace along with the need to reduce embodied carbon and enhance wellbeing. This solution is formed around the highly successful and completely tried and tested approach of an RC or PT flat slab. In the design of the workplace it ticks so many of the necessary performance and operational boxes:

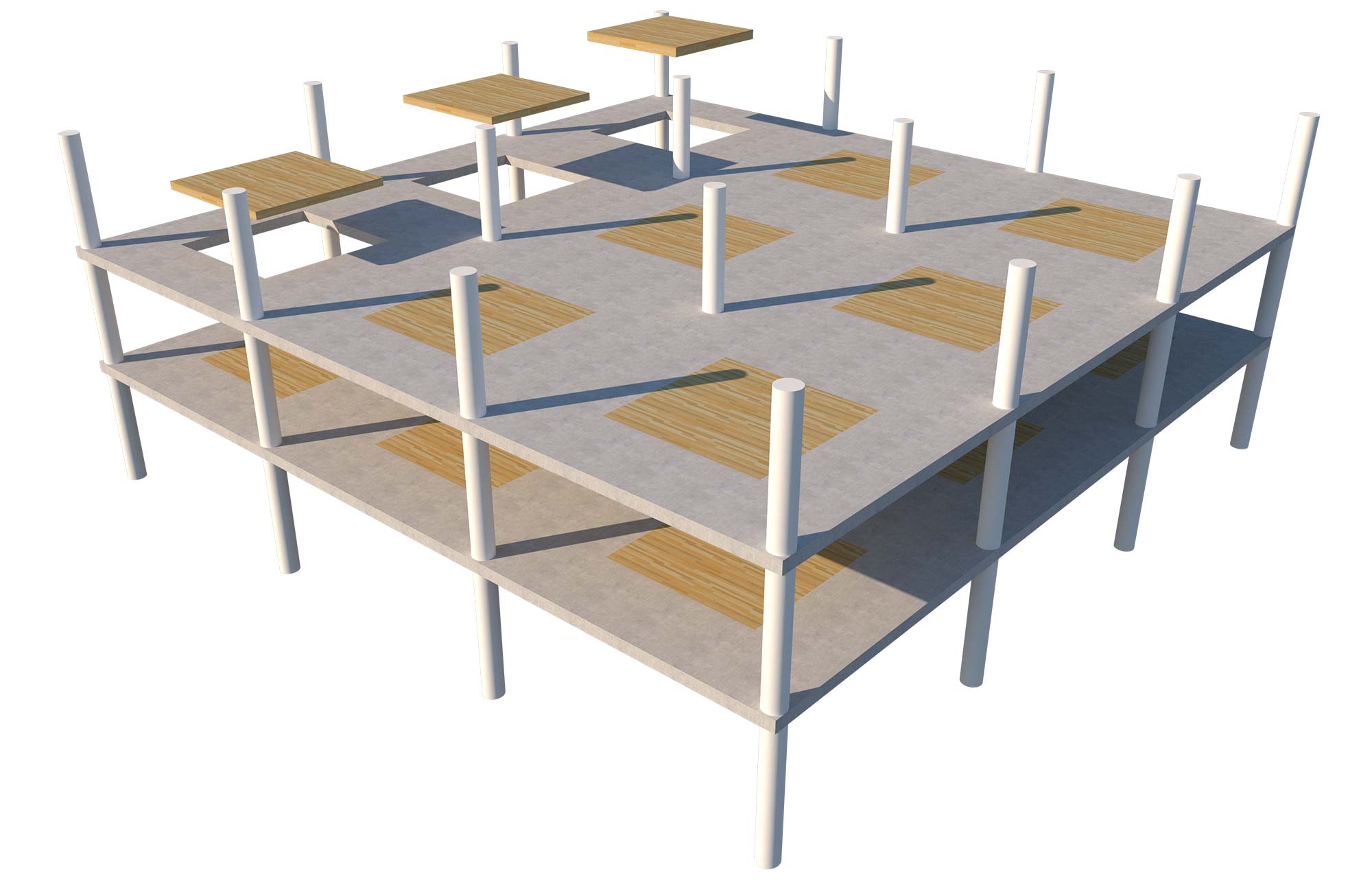

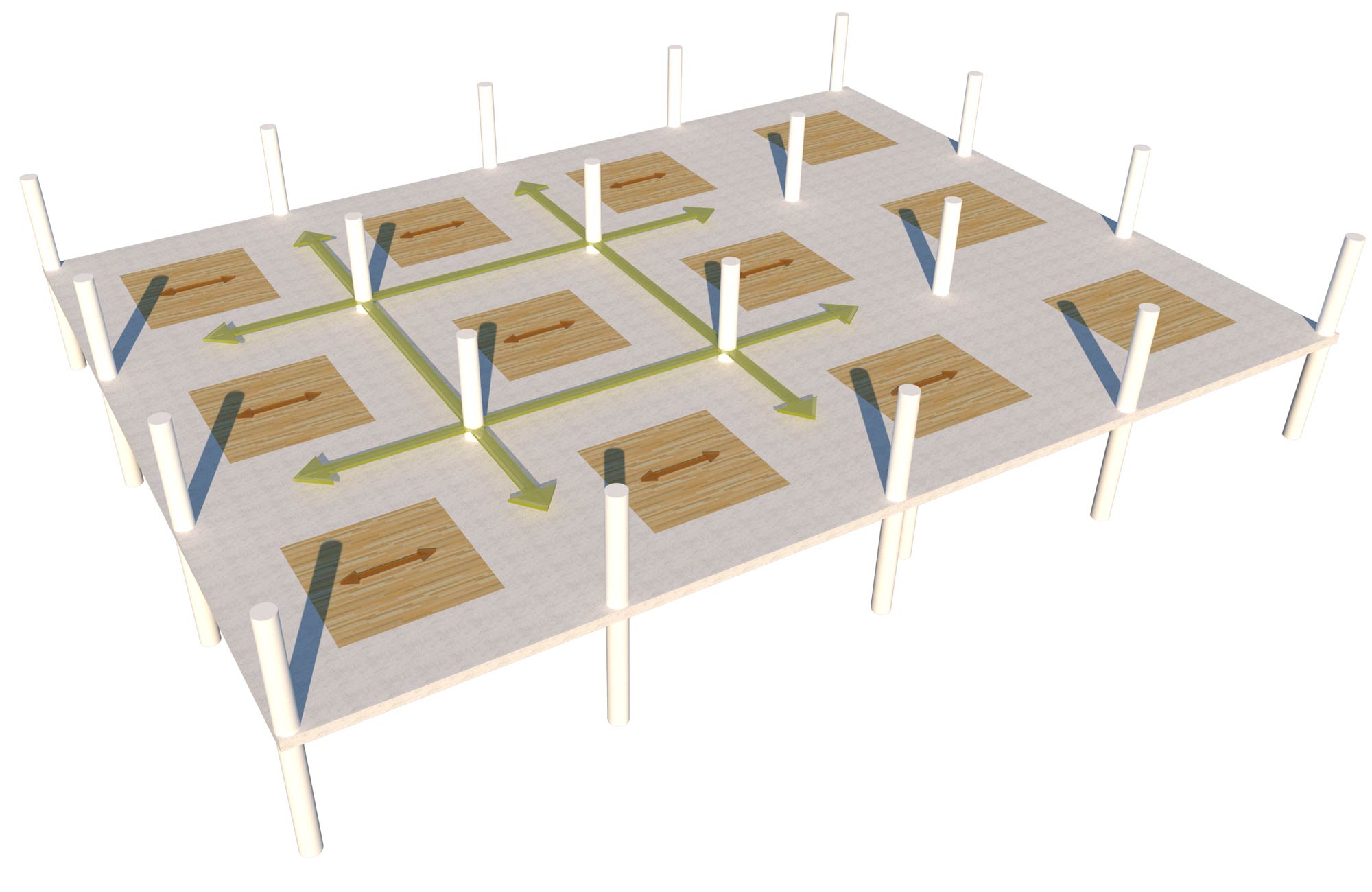

This hybrid solution takes the largely redundant and less critical part of the flat slab (the central belly section) that in many respects is simply floor infill and replaces it with cross-laminated timber (CLT) infill. Because there are similarities in the structural approach of flat slabs and CLT panels, we can easily make this swap where the strength and stiffness of the material is less critical in the overall performance of the floor structure. By optimising the office floorplate grid, we can balance the necessary depth of the RC or PT floor and the CLT, giving rise to a replication of the flat flush soffit and top surface of both portions of structure.

The CLT is detailed in the connections such that the panels can be removed by future tenants over the lifetime of the building, therefore providing an abundance of future inter-floor connectivity which is a selling point so often required but always difficult to provide in such flexibility or in a way that’s relatively simple to implement in practice by a tenant.

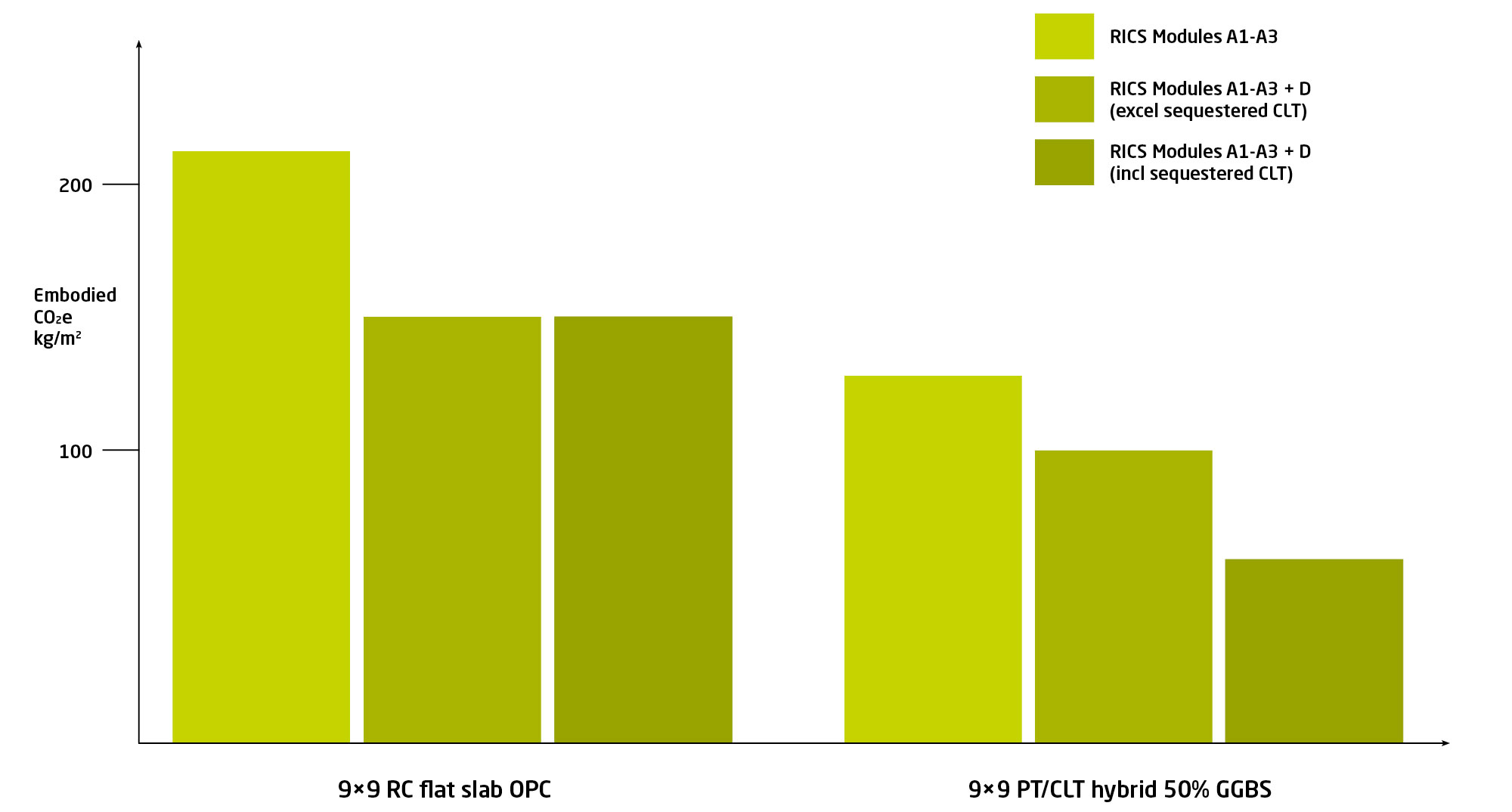

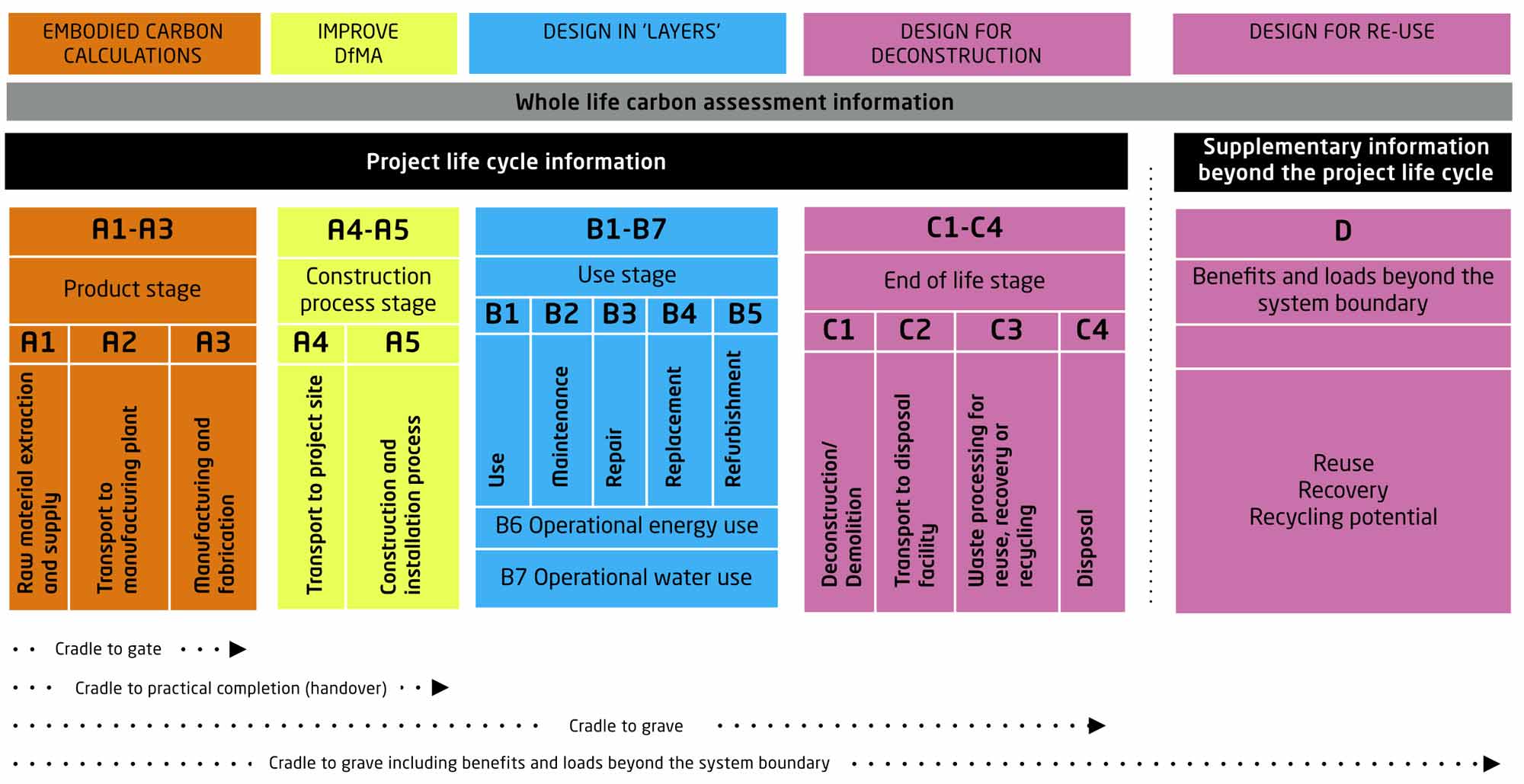

But the critical point is where does this solution compare in embodied carbon metrics? As with all mass timber solutions and RICS embodied carbon counting, the results are very dependent on the way sequestered carbon in the mass timber is assessed. Current guidance advises sequestered carbon counting has to consider current CLT recycling methods, which are largely non-existent and most CLT would be incinerated, therefore the carbon capture lost. Looking forward, we should hope that government requirements and technologies will legislate capture/reuse, thereby maintaining the carbon capture for a significant time beyond the deconstruction of the building.

The figures show the relative reduction in embodied carbon compared to a typical RC (reinforced concrete) study with ordinary Portland cement, through to a post-tensioned /CLT hybrid solution with the CLT infil. The refinement of the concrete slab by adopting PT and 50 % GGBS in addition to the CLT infil reduces the embodied carbon of the floor and framing by 40 % if the CLT is assumed incinerated after use (A1–A3 + D, excl sequestration), or by a more significant reduction of 67 % should we account for full sequestration of the CLT in the future (A1–A3 + D, incl. sequestration). With other elements of the building designed appropriately, this gives most schemes a very good opportunity to achieve the RIBA 2030 embodied carbon target of 500 kg CO2e/m2.

This solution clearly doesn’t go as far as possible in adopting mass timber – we all know we can construct full timber medium-rise commercial buildings – but do they actually tick enough boxes to be truly sustainable by meeting the needs of the modern workplace and providing sufficient durability, longevity and other performance requirements?

The PT/CLT hybrid is primarily a concrete-framed structure, with the CLT components of secondary structural significance; i.e. they can be fully removed without any detrimental effect to the overall integrity of the structure. This is a big deal for many developers and their respective funders and insurers. The fire issues that are becoming (rightly so) harder to meet following the tragedy of Grenfell Tower, especially with the emerging changes to the Building Control Alliance requirements, are more readily met with this type of hybrid solution.

We are in the detailed design/development stage of this solution with a number of projects and clients who have seen the benefits it offers, and with a good wind we will have at least one of these projects realised in the not-too-distant future. We and the client / project teams we are working with have seen and recognised the main benefits the solution offers, which can be summarised as follows: